The Rise of Industrial Automation

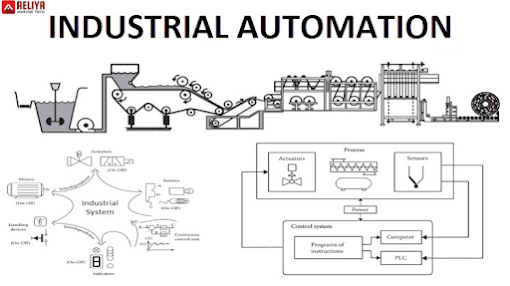

The use of machines and technology to perform tasks that were once done by humans. This shift is reshaping industries worldwide, from manufacturing to logistics and beyond. But what exactly is industrial automation, and why is it becoming so prevalent?

Understanding Industrial Automation:

Industrial automation involves the use of various technologies such as robotics, artificial intelligence (AI), and advanced machinery to streamline processes and increase efficiency in manufacturing and other industries. Instead of relying solely on human labour, companies are now integrating automated systems to perform tasks faster, more accurately, and often at a lower cost.

The Driving Forces Behind Automation:

Several factors are driving the

rise of industrial automation. One of the primary drivers is the quest for

increased productivity and efficiency. By automating repetitive and labour-intensive

tasks, businesses can produce more goods in less time, leading to higher output

and potentially greater profits.

Another factor is the advancement of technology itself. Robotics and AI

have reached a point where they can handle complex tasks once thought to be

exclusive to human workers. These technologies continue to evolve, becoming

more sophisticated and affordable, making automation an increasingly attractive

option for businesses of all sizes.

Benefits of Industrial Automation:

The adoption of industrial automation

offers numerous benefits for businesses:

Improved efficiency: Automated systems can work around the clock without fatigue or breaks, leading to uninterrupted production and faster turnaround times.

Enhanced quality: Machines can perform tasks with precision and consistency, reducing errors and defects in the final product.

Cost savings: While the initial investment in automation technology can be significant, the long-term savings in labour costs and increased productivity often outweigh the upfront expenses.

Safety: By automating hazardous tasks, companies can improve workplace safety and reduce the risk of accidents and injuries to human workers.

Challenges and Considerations: Despite its many advantages, industrial

automation also presents challenges and considerations for businesses:

InitialCosts: Implementing automation systems can require a significant

upfront investment in technology, training, and infrastructure.

Workforce implications: Automation may lead to job displacement for some

workers, requiring companies to retrain employees or rethink their workforce

strategies.

Technical complexity: Integrating automation technology into existing

processes can be complex and may require specialized expertise.

Ethical considerations: As automation replaces human labor in certain

tasks, questions arise about the societal impact, including job loss and income

inequality.

The Future of Industrial Automation:

The trend toward industrial

automation shows no signs of slowing down. As technology continues to advance,

we can expect to see even greater integration of automation across industries.

This shift will likely bring about further improvements in efficiency, quality,

and safety, while also posing new challenges for businesses, workers, and

society as a whole.

Conclusion:

Industrial automation represents a significant transformation in the way we work and produce goods. By harnessing the power of technology, businesses can unlock new levels of productivity and competitiveness. However, this shift also requires careful consideration of the challenges and implications involved. As we navigate this evolving landscape, it's essential to strike a balance between embracing innovation and addressing the human and societal impacts of automation.

Comments

Post a Comment